NJ & NYC Commercial & Residential Garage Door

2026 Guide: Choosing the Right Loading Dock Door for Your Business

Choosing the right loading dock door is crucial for your business's efficiency and safety. A loading dock door affects your workflow, security, and energy costs. It’s not just a simple access point; it plays a significant role in logistics.

There are various types of loading dock doors available. From standard overhead doors to high-speed options, each serves a specific purpose. Consider how often your door will be used. Will it withstand harsh weather conditions? Think about the material as well. Steel, aluminum, or fiberglass options all have different durability levels.

Reflecting on your specific needs can be challenging. It's essential to balance cost and quality. A cheaper option may save money upfront but lead to future repairs. You should also consider safety features, such as visibility and insulation. Weighing these factors can feel overwhelming, but making an informed choice will benefit your operations.

Understanding Different Types of Loading Dock Doors Available in 2026

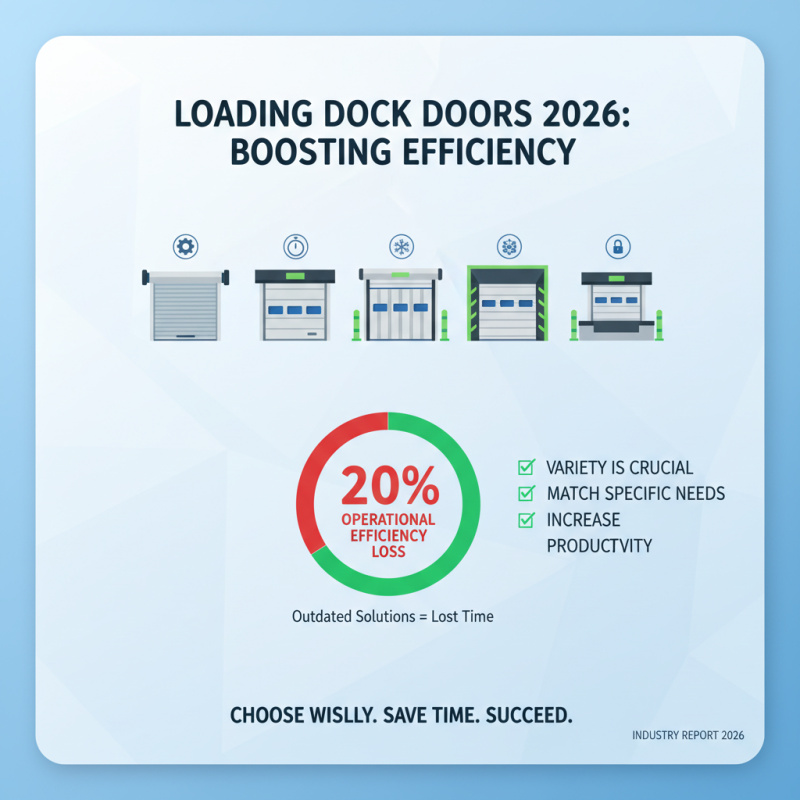

When it comes to loading dock doors, the variety available in 2026 is impressive and crucial for efficiency. A recent industry report noted that organizations lose approximately 20% of operational efficiency due to outdated or poorly matched loading dock solutions. Businesses must consider the specific needs when choosing a door.

There are several types of loading dock doors to explore. Sectional doors are popular for their insulation capabilities and security features. They can reduce energy costs, especially in climate-controlled environments. Rolling steel doors, on the other hand, provide durability and strength. Data shows that businesses report a longer lifespan with these doors, often lasting over 20 years with proper maintenance.

Dock leveller doors are essential for seamless vehicle and warehouse integration. A study indicates that 30% of warehouse accidents occur during loading due to improper equipment. This emphasizes the need for suitable door types to enhance safety and loading speed. Investing in the right door not only boosts productivity but also protects the workforce. Business owners must reflect on their unique operational needs and avoid settling for one-size-fits-all solutions.

Evaluating Your Business Needs for Loading Dock Door Selection

When selecting a loading dock door, various business needs must be assessed. Each operation has unique requirements. For instance, a study by the Warehousing Education and Research Council indicates that 78% of logistics companies prioritize operational efficiency. This data highlights the importance of selecting a door that minimizes wait times and enhances throughput.

Consider the types of goods being shipped. If you handle temperature-sensitive products, an insulated door is essential. According to the National Institute of Standards and Technology, energy loss can increase operational costs by 30%. Thus, investing in a door that maintains ideal conditions is not just practical; it's financially prudent.

Space constraints are another factor. If the area is tight, a folding or sliding door might be more effective. Reflections on past decisions often show that underestimating space can lead to costly redesigns. Incorporating feedback from staff who operate the docks is crucial. Their insights can reveal flaws in a chosen door style or suggest new options.

2026 Guide: Choosing the Right Loading Dock Door for Your Business

| Business Type | Loading Dock Door Type | Traffic Frequency | Insulation Needs | Safety Features |

|---|---|---|---|---|

| Retail Stores | Sectional Door | Moderate | Minimal | Photo Eye Sensors |

| Distribution Centers | Roll-up Door | High | High | Safety Edge System |

| Manufacturing Facilities | Insulated Door | High | Very High | Emergency Stop Button |

| Cold Storage Facilities | Rapid Roll Door | High | Extreme | Motion Sensors |

| Logistics Companies | High-Speed Door | Very High | Moderate | Interlock System |

Key Features to Consider When Choosing Loading Dock Doors

When selecting loading dock doors, several key features must be considered. Durability is paramount. According to industry data, approximately 30% of loading dock incidents result from door failures. Choosing robust materials can reduce downtime and repair costs. Look for doors made from steel or heavy-duty composite materials. These options tend to withstand high traffic and resist damage over time.

Another critical feature is insulation. Energy efficiency plays a significant role in operational costs. Reports indicate that efficient loading dock doors can reduce energy loss by up to 50%. Insulated doors help maintain consistent temperatures within the facility. This can be crucial for temperature-sensitive products.

**Tip:** Always assess the typical traffic and product types handled at your dock. Ensure your choice aligns with the specific demands of your operation.

Also, security features should not be overlooked. Many facilities face theft and damage concerns. Doors with advanced locking mechanisms and impact-resistant technologies can enhance security. However, striking a balance between security and accessibility is vital.

**Tip:** Involve your logistics team in the decision-making process. They can provide valuable insights based on daily operational experiences. This collaboration can lead to a more informed choice.

Comparative Costs and Budgeting for Loading Dock Door Installation

Choosing the right loading dock door involves careful budgeting. Installation costs can vary widely. Reports suggest the average cost of a loading dock door ranges from $2,000 to $10,000. Factors influencing these costs include material, size, and installation complexity. Proper budgeting is essential. Unforeseen expenses can arise during the installation. Plan for a 10% buffer to manage unexpected costs effectively.

Tips for budgeting include obtaining multiple quotes. Each supplier may offer different prices based on the door specifications and installation needs. Don’t rush this process; a thorough assessment can lead to better deals. Consider energy-efficient doors. While the initial investment might be higher, they save on energy costs in the long run. Reports indicate that energy-efficient options can reduce yearly energy costs by up to 30%.

Keep in mind, cheaper isn’t always better. A low-quality door may lead to more repairs. Maintenance costs can accumulate quickly. Analyzing total cost of ownership is crucial. Long-lasting doors save money over time. Look for doors with good warranties. Evaluate factors like durability and insulation to ensure your investment pays off. This careful consideration can help avoid costly mistakes.

Maintenance Tips for Ensuring Longevity of Loading Dock Doors

Loading dock doors are essential for operational efficiency. They endure heavy usage, leading to wear and tear. A study indicates that improper maintenance can decrease a dock door's lifespan by up to 30%. Therefore, regular inspection is crucial. Identify issues early for timely repairs. Look for wear on seals and hinges. Ensure that the operational mechanisms function smoothly.

Lubrication is vital. It keeps moving parts from seizing up. Research shows that lubricated systems can extend door life significantly. However, excess lubrication may attract grime. Balance is key here. Additionally, track temperature fluctuations. Extreme weather can warp materials. If you notice any abnormal noises, address them immediately.

Cleaning the door's surface is more than cosmetic. Dirt can accumulate and damage finishes over time. Use a non-abrasive cleaner to maintain appearance and functionality. Smart maintenance practices pay off. A well-kept loading dock door not only ensures safety but also enhances overall efficiency. Regular reviews can prevent costly replacements down the line.

Related Posts

-

How to Choose the Right Loading Dock Door for Your Business Needs

-

How to Find the Right Phone Number for Overhead Door Services in Your Area

-

Why Your Garage Door Opener Is Not Working and How to Fix It

-

The Best 10 Benefits of Rolling Steel Doors for Your Business Security

-

Top 5 Rolling Steel Doors for Ultimate Security and Convenience

-

Exploring the Benefits of Installing a Garage Door with an Integrated Door: Functionality Meets Convenience